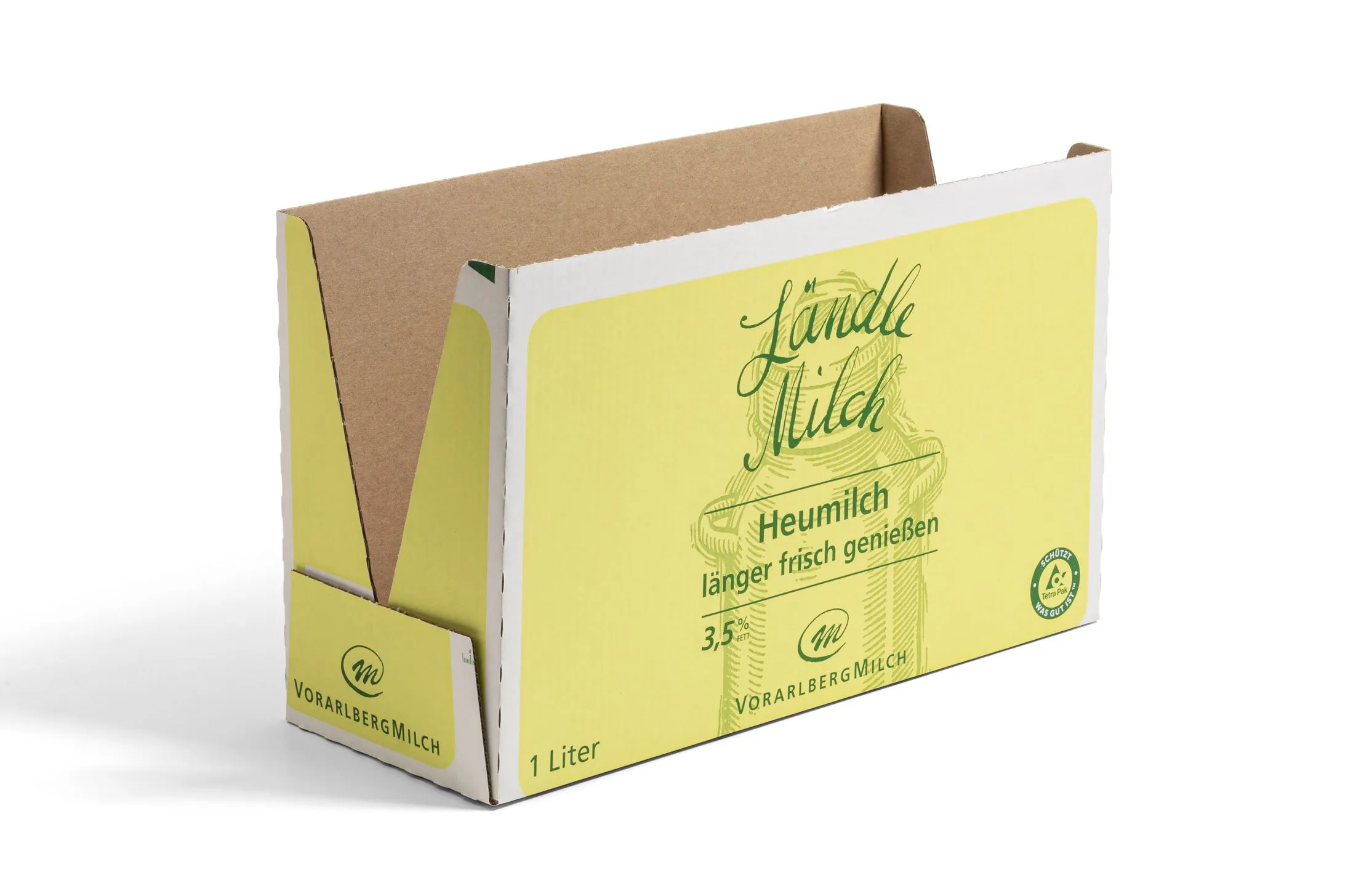

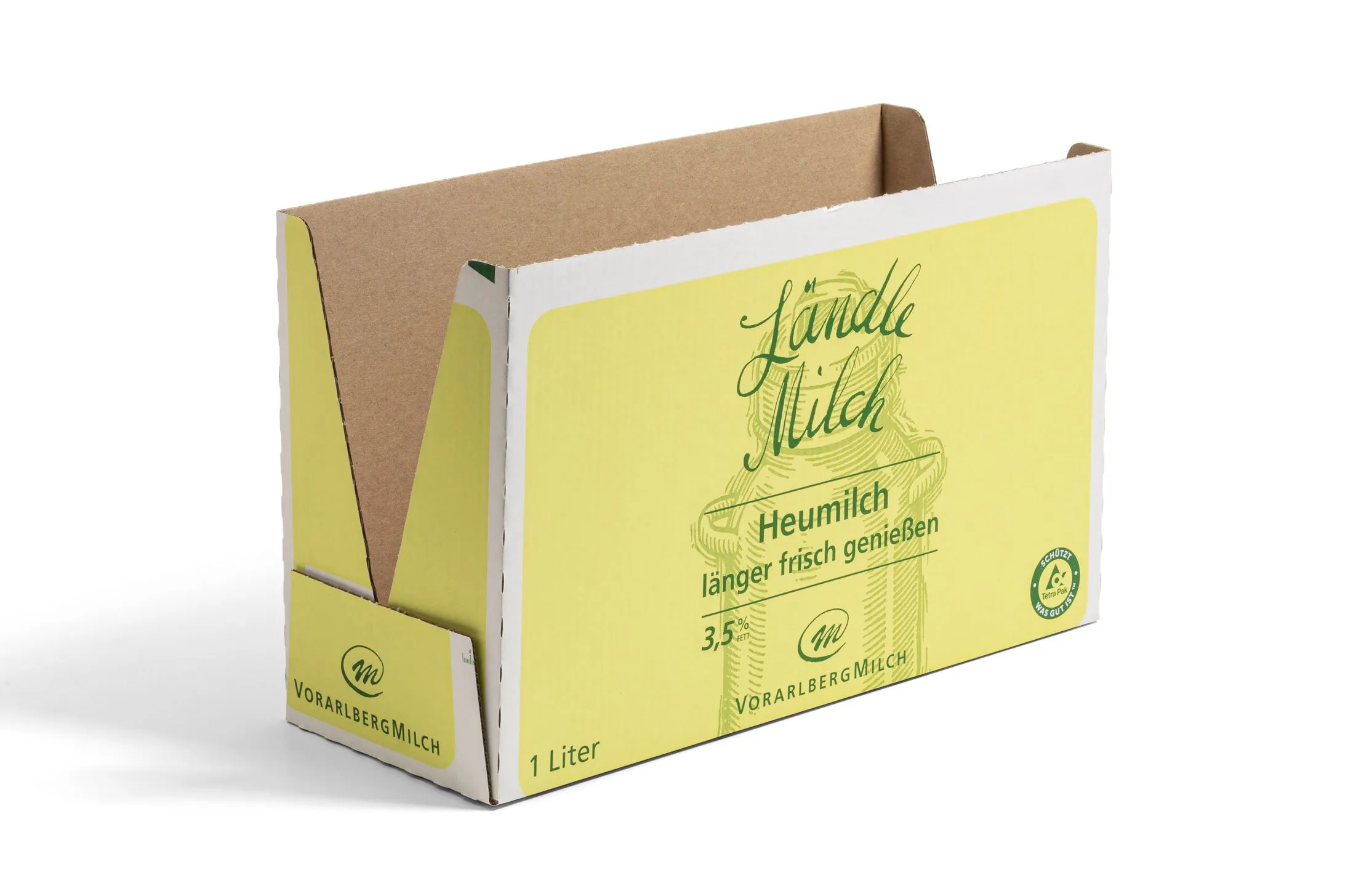

The automatic box from Flatz.

What can you really say about a corrugated board box? If it comes from Flatz, a great deal because the automatic box is in fact in a world of its own. It impresses customers with its high stability, the bottom which straightens out automatically, and the way it can be stored in a small space, as well as being delivered collapsed flat.

The automatic box embodies lots of expertise well beyond the usual standard. We achieve the highly precise punching, which actually enables customers to implement automated packaging processes with millimeter precision, by using BOBST punching machines. The Mastercut 1.7 is equipped with an electronic print mark control feature – ‘Power Register’ – which guarantees an accuracy of +/- 0.1 mm between the punching crack and printed image or sheet edge. With automatic raw material feeding, gBreak, automatic palletization and a maximum output of 7,500 sheets per hour, the automatic box is produced on one of the world’s most state-of-the-art punching lines.

As stability is the most important aspect for cardboard packaging boxes, we solve the challenge of folding relatively strong material using a method that has been patented by Flatz: Liquid Creaser. This involves a special liquid being applied to the path of the fold which then evaporates shortly after the folding process.

It’s good to know that a cardboard box from Flatz is much more than just a box. Ultimately, you entrust it with the most valuable thing your company offers.

Hängt von den Anforderungen ab: Isolierend mit Transportschutz, Mehrweg mit einfachem Handling, hoher Transportschutz und doch leicht und natürlich auch die Optik. Geht alles, fragen Sie uns einfach.