A product that is as consistently eco-friendly as CoffeeB requires a packaging solution that is just as sustainable. We've made one: With the revolutionary CoffeeB packaging for the no-capsule system.

The coffee capsules of CoffeeB do not feature any aluminum or plastic – they have no outer packaging at all. The coffee scoop is placed directly inside the coffee machine, and the used coffee powder can then easily be composted. The same demand was set for the coffee packaging. Challenge accepted: Flatz magically produces a wafer-thin layer on the molded fiber packaging – making it suitable for direct contact with food and satisfying the highest barrier requirements.

This means together with CoffeeB we are reducing the amount of packaging waste: This is vital because around 70% of the aluminum or plastic coffee capsules sold around the world end up as landfill. This represents tons of waste that can now be prevented thanks to CoffeeB and Flatz.

With the Flatz innovation, a wafer-thin layer is bonded to the fiber mold, pressed on and sealed. This allows direct contact between the fiber and food. A revolution for the packaging industry.

The primary molded fiber packaging from Flatz allows us to achieve the goals set by the EU: reducing the consumption of resources, reducing packaging waste and promoting recycling. You too can rely on our forward-looking, ecological molded fiber packaging.

The raw material used to make our packaging for direct contact with food is fresh fiber. It is 100% recyclable and shows once again what we're all about: optimum recycling of packaging materials. This closed recycling loop benefits you, your customers and above all the environment.

Tell us your barrier requirement, shelf-life score or use-by date – we'll develop bespoke molded fiber primary food packaging for you.

We can cater for all barrier requirements: oxygen barriers, moisture barriers, gas barriers, light barriers and aroma barriers.

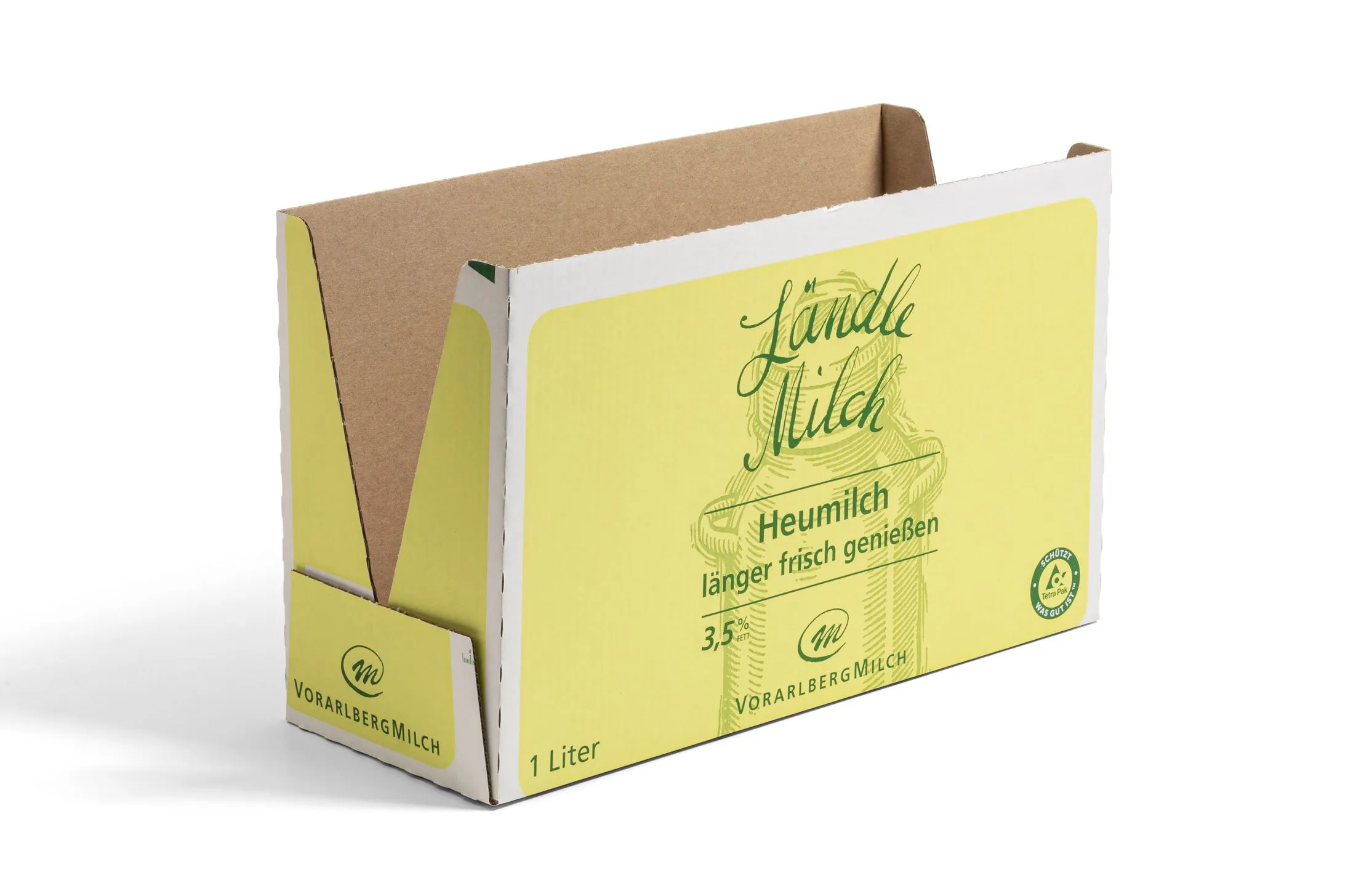

Molded fiber packaging has a characteristic color and sustainability is automatically part of its DNA in visual terms. But we also produce bleached and white molded fiber solutions as packaging for your food. Dyes of different colors are possible for very large quantities.

Flatz manufactures molded fiber packaging for direct contact with food

T +43 5574 83 290 0

F +43 5574 83 290 205

verpackungen@flatz.com

As one of Europe's leading packaging manufacturers, we offer our food customers a wide range of different paper-based materials that will enable us all to have a sustainable future.

Hängt von den Anforderungen ab: Isolierend mit Transportschutz, Mehrweg mit einfachem Handling, hoher Transportschutz und doch leicht und natürlich auch die Optik. Geht alles, fragen Sie uns einfach.